By TONY BONAVIST

I’ve taken considerable pride in my ability to make fishing rods. By “make,” I don’t mean actually making the rod blank itself, but making the cork grips, installing reel seats, and attaching and varnishing the guides. Making rod blanks out of today’s synthetic materials-like graphite, carbon fiber and fiberglass-are manufacturing processes best left to companies that have the technology to do that.

Constructing rod blanks from bamboo (cane) is an entirely different exercise. While I’m pretty handy with tools, I’ve never even thought about making a bamboo rod blank. Nevertheless, it can be accomplished by almost any person who has infinite patience and a decent amount of skill with tools like planes, small saws, lathes, drills and the like.

That does not mean that making a bamboo fly rod blank is easy; far from it. Folks that decide to get involved with all the steps required to complete a cane fly rod usually are fly fishermen who have fished with, and have a great affection for, bamboo. Sometimes, but not always, folks interested in building fly rods out of bamboo will apprentice with, or take a course provided by, other bamboo rod makers. A few are completely self-taught. And then, of course, there are videos on YouTube and other media that have all types of self-help/teaching aids available these days.

According to the literature, bamboo became the preferred material for making fishing rods, including fly rods, when Solon Philips made the first six-strip hexagonal rod from Calcutta cane in 1859. Then in 1874, the H.L. Leonard Rod Company began to build fly rods exclusively from cane. The company continued to make bamboo fly rods, under various names, until a fire destroyed the shop in 1964.

In that same era, rod makers like Jim Payne and F.E. Thomas made hundreds, if not thousands, of premium-quality bamboo fly rods, some of which sell for thousands of dollars. Other manufacturers, like Horrocks-Ibbotson, Heddon and Montague, mass-produced cane fly rods. Orvis joined the ranks around 1850, and still makes bamboo fly rods.

As time progressed, makers like Carpenter, Dickerson, Gillum, Winston, Brandon, Thomas and Thomas, Howells, Garrison, Powell, Aroner, Young and Ramanauskas, joined the ranks of quality rod makers. Some of those men and companies continue to make extremely high-quality rods today.

While graphite and even fiberglass have been the preeminent rod materials for the last 30 years or so, there has been a resurgence in bamboo rods. In the last 15 or 20 years, several new builders have joined the ranks of high-quality rod makers. While I don’t know them all, the list includes Chris Raine, James Reams, Dennis Menscer and others.

I have two Raine rods, an eight-foot, three-inch one and an eight-foot, six-inch rod. When I found Chris Raine, I asked if his rods would handle large trout. He assured me they would, and provided a video of an angler landing a very big steelhead on one of his rods. I was sold. Chris’ premium rods are hollow-built and flawlessly crafted, with superior varnish work, windings and grips. His rods are true works of fly fishing art, and I believe he is one of the best rod makers of this era.

So what does it take to make a bamboo fly rod from scratch?

First, you’ll need a source of bamboo. While Calcutta cane was used, it is widely agreed by knowing rod makers that Tonkin cane is the best bamboo available to make fly rods. There was an embargo on that material from 1950 until 1971. Since the embargo ended, many rod makers believe that “pre-embargo” Tonkin cane is the superior bamboo. Bamboo is available from several sources, with Demarest probably the best known.

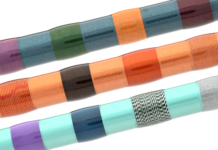

Once a maker has a supply of cane, called “culms,” the bamboo must be aged, split into desired lengths and widths, based on the tapers, that will define a particular fly rod. That process is done by hand. Next, the sections are hand-planed or machine beveled to the required taper, with tolerances as small as 1/1000th of an inch. The tapered sections are then glued into a six-sided blank, which is wrapped with string to facilitate drying. When the glue has set, the nodes are sanded or planed smooth. The sections are then heat-treated to provide the desired level of stiffness, or action. The metal ferrules which join the sections together for fishing are then pinned or glued in place. The cork grip and real seat are added and the blank treated to several coats of varnish. Last, the guides are spaced, wound with thread, and then they are varnished. After all those steps, the rod is complete, and set aside for the varnish to dry completely and cure.

I’m told it takes about 40 hours of painstaking effort to craft a bamboo fly rod! Many rod makers charge about $2500 for one of their rods, which seems like a lot, but it amounts to about $60 per hour. Not a lot, considering today’s wages and the skill involved.

In comparison to bamboo, graphite rods, while superb fishing instruments, are lifeless tools, mass-produced and efficient. Bamboo rods are truly fly fishing works of art, beautifully crafted, with the finest hardware and grips. They reflect the heart, soul and personality of each rod maker, and feel alive in the hand. While most of today’s anglers use graphite rods, there is a cadre of anglers that prefer bamboo. I know what my preference is!

Credit: Source link