The outdoor industry, more than most, is keenly aware of the effects of climate change and, in particular, the need to create greener supply chains. It’s the reason more than 377 outdoor brands have joined the Plastic Impact Alliance, committing to making our industry more sustainable by eradicating single-use plastic from their businesses.

Although everything from materials to manufacturing contributes to a company’s carbon footprint, it’s end-of-the-line packaging that really adds up and is often unable to be recycled curbside. Still, it’s arguably one of the easiest things to change and make more sustainable (not to mention, it serves as a significant touchpoint with customers, especially as ecommerce continues to trend upwards).

Only about 9 percent of all plastic waste is currently recycled and as such, single-use plastic packaging accounts for nearly half the plastic waste found in nature. In August, prAna, an early member of the Plastic Impact Alliance and a leader in sustainable, outdoor fashion, announced the Responsible Packaging Movement, a program designed to create industry-wide change. Since 2010, prAna has successfully eliminated more than 17 million polybags from the supply chain and its new initiative takes it a step further by collaborating with other industry brands.

This year, prAna announced its new Responsible Packaging Movement, a program designed to create industry-wide change. Courtesy.

In line with the Plastic Impact Alliance and prAna’s mission of sharing knowledge and transforming the industry together, we’ve compiled this list as a resource for outdoor brands. From mailers to labels, protective wrapping to polybags, here are five companies out to revolutionize how we package and ship products. The first three innovations on this list were recent winners of the Sustainable Packaging Coalition 2020 Protective Packaging Design Challenge.

Returnity

The product: Chrysalis is a reusable shipping bag designed to replace poly-mailers and reusable shipping boxes.

How it works: Brands work with Returnity to design mailbags that, once used for shipping, can be flipped inside out by the customer and transformed into a tote, duffle, or makeup bag. The boxes are made for companies engaged in a circular shipping model.

“Our view is that companies will not scale the use of reusables if it doesn’t make sense financially, so we enable them to make the switch by making it cost-effective,” said Returnity CEO Michael Newman.

Returnity believes its packaging creates perfect social media moments once in the customer’s hands.

“In addition to cardboard boxes and poly-mailer bags being wasteful, they’re just boring,” said Newman. “For so many retailers, this is the one physical touch point they have with the consumer. When you ship something in a reusable package, consumers take notice and love it.”

Environmental credentials: All bags and boxes are made from recycled plastic bottles. Returnity is also working with a household name in outdoor fabric to turn used or deadstock fabrics—things that may have failed color matching or quality control and might otherwise be landfilled—into reusable shipping bags. Additionally, all of Returnity’s boxes have a layer of rigid plastic in between them, meaning they outperform cardboard in terms of strength, durability, and product protection. Returnity guarantees its packaging for 40 shipments and will even take products back from clients at the end of their life span in order to handle the recycling of the material.

Applications for the outdoor industry: Returnity’s willingness to work with brands on a case-by-case basis means its industry applications are endless. Although the company’s model is similar to LimeLoop, which is used by Toad & Co, it differs in the respect that its reusable packaging isn’t leased.

“I’m super proud of our ability to adapt our reusables in a way that makes sense for almost any product,” said Newman. “The thing that we’re working on now is really enabling systems, so that if your company isn’t inherently circular we’re able to help you get there.”

Returnity counts O’Pros Fly Fishing and Camp Rents among its current clients. In the coming weeks they will add a yet-to-be-name gear rental company plus another big name in outdoor apparel.

Mushroom Packaging

The product: High-performing packaging made from hemp and mycelium that resembles pulp packaging or an egg carton, and easily could replace similar plastic versions as well. Additionally, it’s cost competitive, thermally insulating, and water resistant.

How it works: Every piece of Mushroom Packaging (powered by Evocative Design) is custom designed, using CAD software, and grown in just seven days. The product is a living material and spends four days in its tray before being removed to grow for two more days, and finally, dried for one to disable future growth.

Environmental credentials: Mushroom Packaging takes just 30 days to break down in a home compost, no industrial composting required. (It takes 180 days in a marine compost.) Consumers simply have to break the packaging into small pieces and place it outside in the soil, allowing nutrients to return to the earth. Additionally, the trays used to grow the packaging are reused hundreds of times.

Applications for the outdoor industry: Mushroom Packaging has distribution centers in the U.S., Europe, Oceania, and the U.K. Paradise Packaging, located in California, is the main hub for growth and distribution across the U.S. and does have some standard shapes available. Incredibly versatile and with custom options available, this packaging could be used on everything from ski goggles to fly rods, from solar lights to camping stoves, or anything that benefits from a more rigid form of packaging.

Flexi-Hex

The product: A range of plastic-free packaging solutions made from recycled cardboard that use a honeycomb design and are ideal for replacing bubble wrap.

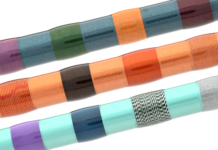

Flexi-Hex utilizes a unique structure that allows it to wrap a wide variety of objects safely. Courtesy.

How it works: The hexagonal cellular structure of Flexi-Hex means it can wrap a wide variety of shapes, sizes, and materials, including glass. Flexi-Hex Air is a lighter, tissue paper-based packaging ideal for smaller, fragile objects.

Environmental credentials: Flexi-Hex’s mission is simple: remove plastic from the packaging industry and raise awareness of the threats currently facing the world’s oceans. Flexi-Hex is nontoxic, reusable, biodegrades readily, and is made of 100 percent recycled cardboard. The company is also currently investigating bio-adhesives in order to remove its reliance on petroleum-based glue.

Although much more low-volume than its plastic counterparts, Flexi-Hex is still manufactured in China and shipped around the world (distribution accounts for the majority of its carbon footprint, although the company does purchase carbon offsets to compensate). Internally, every Flexi-Hex employee also gets a personalized carbon footprint report complete with recommendations on how they can improve things like their travel habits, diet, and home energy use. As of 2020, the company is carbon-negative according to conservation organization Mossy Earth.

You can read the company’s full 2020 sustainability report here.

Applications for the outdoor industry: Flexi-Hex can be used to protect surf boards, skis, snowboards, bikes, small electronics, water bottles, tent poles, sunglasses, helmets, oats, lanterns, coolers—you get the idea.

Vela

The product: A durable, paper polybag alternative, Vela bags are weather resistant and protect their contents from humidity, moisture, and dust.

The Vela bag was originally designed for apparel companies, but its potential uses extend much further. Courtesy.

How it works: A product of family-owned Seaman Paper, a company that now focuses on lightweight paper solutions used in packaging, the Vela bag officially launched at the beginning of this month. Although the bag was designed with apparel companies in mind, it has potential beyond that.

“We’re in testing with lots of global apparel brands whose names you would know,” said Seaman Paper’s VP of business development, Julie Skibniewski. “What’s been surprising to us is the non-apparel inquiries we’ve had from consumer products companies.”

Environmental credentials: Vela bags are made from paper, one of the most highly recyclable products in the world. What’s more, the Vela bag is made from Forest Stewardship Council-certified, sustainably harvested paper fibers; globally, FSC is considered the strongest system of forest management. Since Vela bags can be recycled four to six times, they also promote a circular economy where maximum value is extracted from raw material. Finally, Seaman has partnered with sustainable solutions firm South Pole to calculate the carbon footprint of producing Vela bags and to purchase corresponding carbon offsets.

Applications for the outdoor industry: In addition to prAna, the women’s fashion brand Mara Hoffman and sustainable clothing brand Outerknown are already using Vela bags.

“There’s really a limitless opportunity for Vela bags,” said Skibniewski. “Anywhere you’re currently using plastic, you can use a Vela bag.”

EcoEnclose

The product: EcoEnclose, based in Louisville, Colorado, isn’t a new company but its product line is extensive—from mailers to boxes, packing tape to hemp twine—and constantly evolving. We particularly like their focus on shipping supplies, specifically zero-waste shipping labels, which the company claims are the world’s most eco-friendly.

How it works: Companies can request free, individual samples of specific products or full sample kits. EcoEnclose has the capacity to serve companies of all sizes, whether you need 1,000 units or 5 million. Additionally, the majority of its products can be custom branded.

Environmental credentials: EcoEnclose offers two types of zero-waste shipping labels, the first being 100 percent recycled white labels, compatible with laser and inkjet printers, which come on EcoEnclose’s 100 percent recycled and curbside recyclable liners. The second option is direct thermal labels that are compatible with standard thermal printers, also on the Zero Waste Release Liner. There are also several tape options that are better than the typical plastic stuff, including Cello Carton Sealing Tape, which combines cellulose backing with a natural rubber adhesive, making it plant-based, renewable, and biodegradable.

By 2030, EcoEnclose hopes to be an “ecologically net positive” company, meaning that its products, operations, and supply chain are a positive, regenerative force for the planet. The company has a comprehensive sustainable packaging framework and is committed to innovation.

Applications for the outdoor industry: EcoEnclose’s outdoor industry clients already include La Sportiva, United By Blue, Adidas, and Fjällräven.

Credit: Source link