David Watt had an idea.

Aaron Hartman helped bring it to life.

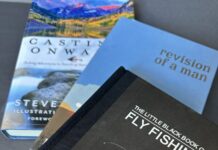

Watt of North Huntingdon collaborated with Hartman of Peters to design the CigarmBand for fishermen. Watt wanted to be able to smoke a cigar while having both hands available to cast a net.

He drew a picture of an armband that has a clip for a cigar so the user can take a puff, push it to the side and reel in a fish.

“I got a ton of help from Aaron,” Watt said. “I had been thinking about this idea for a while because I believe fly fishing and cigars are nostalgic. I decided to go for it after a friend suggested I reach out to Aaron.”

Hartman owns Creation Labs, a maker space in The Galleria of Mt. Lebanon. The location is equipped with 3D printers, laser cutters, 3D scanners, design software, coding programs and more.

Pretty much anything anyone can think of, Hartman can make, he said.

“The capabilities of 3D printing are truly endless,” said Hartman. “The only question we need to answer is what do you want to make? Choose from a vast array of files available on the internet, have a file designed by our team, or we can teach you how to create your own.”

Watt described his vision to Hartman and said when he saw what Hartman had made, it was better than imagined.

“Aaron is a problem solver,” Watt said.

Hartman is happy to be a problem solver, as well as help people design and make their own.

Creation Labs offers memberships starting at $49.95 per month. Members have unlimited access to the makerspacemaker spaceand receive a 50% discount on classes as well as 20% off of retail merchandise.

Classes include 3D printing and manufacturing and 3D modeling and design. One hour is $39.95 and $19.95 for members.

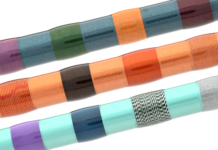

Other prototypes Hartman has made include The Whistle Shield, a whistle that when blown by a professional basketball referee directs any particles from a person’s mouth downward. He’s also made flowers with layers of colors and can create a person’s likeness by scanning them and printing a 3D miniature figure. The objects originate as a digital file. Physical objects are made by extruding molten plastic, called filament, in thin layers, one on top of another, until the desired shape is formed. Creation Labs sells filament in several colors.

The first step is to find a file on sites such as thingiverse.com, pinshape.com or cult3d.com. If you can’t find the file you, want Creation Labs can help design what you want or you can create a design yourself.

Hartman is helping Pittsburgh rap artist Harvey “Frzy” Daniels create a “Black Panther” costume. Daniels asked his friends and family to donate money to help print the outfit. Daniels said the “Black Panther” has been an idol since Daniels was young.

“To see Africa have such a powerful superhero and king resonated with me,” said Daniels, an East Liberty native. “In my everyday life, I see myself as a king and thanks to Aaron, I have a chance to become the Black Panther as well. I can’t wait to show this off. Aaron is a good dude. It is amazing what he can make.”

Glenn Johnson, a former researcher and programmer for IBM who lives on Mt. Washington, has created items in the maker space.

“This space is attractive to me,” Johnson said. “I like the concept. It is great technology and the quality is great. This is the first shop like this that I have ever seen.”

Once the design is created, Creation Labs can make as many as a customer wants and provide technical drawings for injection molding, a manufacturing process for producing parts in large volume.

Hartman began doing 3D print services from his living room. In 2016, he left a mechanical engineering job to open a maker space in South Hills Village. He moved the business to a bigger space in the Galleria in June 2020.

“I have been making stuff my entire life,” Hartman said. “I used to design machinery in steel and concrete and now plastic.”

His son, Ty Hartman, helps in the store. He said he likes working there because it expands his creativity. He has helped with the website as well as the displays in the shop as well as assisting customers with their ideas. Ty Hartman will print a test product and help refine the final piece.

“We’ll take your project from a napkin sketch,” said Hartman, who calls himself chief executive maker. “And make it into a real product you can hold in your hand.”

Or in Watt’s case, on your arm.

JoAnne Klimovich Harrop is a Tribune-Review staff writer. You can contact JoAnne at 724-853-5062, jharrop@triblive.com or via Twitter .

Credit: Source link