Glendale High School engineering design technology student Donald Dove, 18, of Coalport built a magnetic fly fishing reel from scratch using computers and a 3-D printer.

He made the fly fishing reel for his school project at the Greater Altoona Career and Technology Center.

“I love being outside and I hunt and fish so I decided to do something that I really enjoy,” Dove said.

He said he is an avid fly fisherman and ties his own flies so he decided to make his own reel.

To make the reel, he reverse engineered a Crystal River fly fishing reel that he owned.

He took the reel apart, used a 3-D printer to model all of the reel’s 32 parts, and used a 3-D-printer to build the parts from scratch.

In all, it took about eight school days to 3-D model all of the parts and three days to print them.

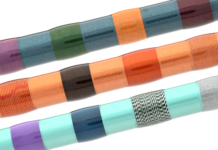

The material the 3-D printer uses are filaments wound on spools. The printer heats up and melts the material and uses it to make solid plastic objects, Dove said.

It is a slow process, the larger parts took about two and a half hours each to print, but the the smaller parts took substantially less time.

Dove said the biggest challenge he had to overcome is getting all the parts constructed so they all fit together properly and operate together smoothly because if the size of a part is off by even a small amount, the reel doesn’t operate properly.

But he got it all to work and he put it on one of his fly fishing rods. He tested it out at Glendale Lake and a few local streams and even caught a few fish with it.

Despite the challenges, Dove said he was pleased with his project.

“It was definitely a lot of fun,” Dove said. “And I learned a lot of new things.”

Dove said he learned, at least on a small scale, what manufacturers go through to design and produce a product and how to overcome problems during the process.

After graduating high school, Dove said he would like to get a career in CAD, (computer aided design.)

Credit: Source link